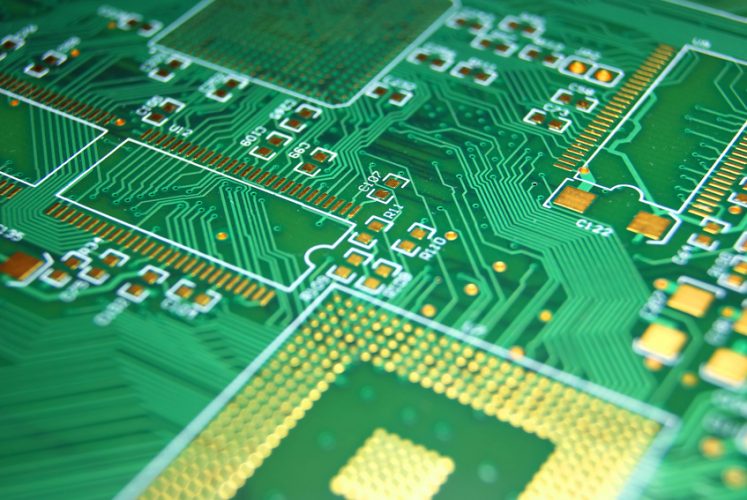

Flexible printed circuit boards (PCBs) have emerged as a game-changing technology in the realm of modern electronics, revolutionizing the way electronic devices are designed and manufactured. Offering a unique blend of flexibility, reliability, and space-saving advantages, flexible PCBs have become a cornerstone in enabling the development of innovative and compact electronic products. In this article, we will delve into the world of flexible PCBs, exploring their benefits, applications across various industries, design considerations, manufacturing processes, and future trends in technology. Join us as we uncover how flexible PCBs, provided by PCB-togo Electronic, Inc., are shaping the landscape of electronic engineering and propelling the evolution of cutting-edge electronics.

Understanding Flexible Printed Circuit Boards (PCBs)

Flexible Printed Circuit Boards (PCBs) are like the yoga masters of the electronics world – they can bend, twist, and contort themselves to fit into tight spaces and unconventional shapes. These flexible wonders are made of layers of flexible substrate that allow for intricate designs and compact arrangements.

Benefits of Using Flexible PCBs

Using Flexible PCBs is like investing in the electronics equivalent of a pair of stretchy pants – they offer a range of benefits such as improved reliability, reduced space requirements, and enhanced durability. These bendy boards are changing the game for modern electronics design.

Advantages of Flexible PCBs in Modern Electronics

Enhanced Flexibility and Durability

Flexible PCBs can withstand the twists and turns of everyday use, making them ideal for products that require frequent movement or bending. Say goodbye to rigid boards that crack under pressure – flexible PCBs are here to save the day!

Space and Weight Savings

In a world where smaller is often better, flexible PCBs shine by providing a compact and lightweight alternative to traditional rigid boards. These flexible powerhouses can be bent and folded to fit into tight spaces, making them a favorite among designers looking to save precious real estate in their electronic devices.

Improved Signal Integrity and Reliability

Flexible PCBs offer a stable and consistent signal transmission, ensuring that your electronic devices operate smoothly and without interruptions. With reduced electromagnetic interference and signal loss, these bendable boards are the unsung heroes of signal integrity.

Applications and Industries Benefiting from Flexible PCBs

Consumer Electronics

From foldable smartphones to wearable fitness trackers, consumer electronics are embracing the flexibility and versatility of Flexible PCBs. These innovative boards are paving the way for sleeker designs and smarter devices that seamlessly integrate into our daily lives.

Medical Devices

In the world of medical devices, reliability and flexibility are paramount. Flexible PCBs are revolutionizing the healthcare industry by enabling the creation of compact and durable devices that can withstand the rigors of medical environments. From pacemakers to diagnostic tools, these bendable boards are saving lives in more ways than one.

Aerospace and Defense

When it comes to aerospace and defense applications, flexibility can be a game-changer. Flexible PCBs are integral to the design of high-performance aircraft, satellites, and military equipment, where space constraints and reliability are non-negotiable. These flexible wonders are soaring to new heights in the skies and beyond.

Flexibility and Design Considerations in Flexible PCBs

Material Selection for Flexibility

Choosing the right materials is key to ensuring the flexibility and durability of your Flexible PCBs. From polyimide to polyester, selecting the appropriate substrate and copper thickness can make all the difference in the performance and lifespan of your bendable boards.

Design Guidelines for Flex PCB Layout

When it comes to designing Flexible PCBs, attention to detail is essential. Factors such as bend radius, component placement, and trace routing can impact the flexibility and functionality of your boards. By following design guidelines and best practices, you can ensure that your Flexible PCBs perform flawlessly in any application.

In a world where flexibility is the name of the game, Flexible PCBs are leading the charge towards a more adaptable and innovative future in electronics design. With their bendable capabilities and reliable performance, these versatile boards are transforming the way we think about modern electronics. Thank you, PCB-togo Electronic, Inc, for bringing flexibility to the forefront of electronics innovation!

Manufacturing Process of Flexible PCBs

Subtractive vs. Additive Manufacturing Methods

When it comes to creating flexible PCBs, two main methods are used: subtractive and additive manufacturing. Subtractive manufacturing involves etching away excess material from a copper-clad substrate to reveal the desired circuit pattern. On the other hand, additive manufacturing builds up the circuit layer by layer using techniques like inkjet printing or 3D printing.

Fabrication Techniques for Flexible PCBs

Fabrication of flexible PCBs involves a series of steps including designing the circuit layout, printing the circuit pattern onto a flexible substrate, and then laminating it with protective materials. Techniques like screen printing, digital printing, and laser ablation are commonly used to create intricate circuit designs on flexible materials.

Future Trends and Innovations in Flexible PCB Technology

Integration of Flexible PCBs in Wearable Technology

One of the exciting trends in flexible PCB technology is its integration into wearable devices. Flexible PCBs allow for designs that can conform to the shape of clothing or accessories, enabling the development of smart textiles, fitness trackers, and even medical monitoring devices that are comfortable to wear and unobtrusive.

Advancements in Flexible Substrate Materials

Another key area of innovation in flexible PCB technology is the development of advanced substrate materials. Researchers are exploring new materials that offer enhanced flexibility, durability, and performance characteristics. This includes materials like polyimide, liquid crystal polymer, and even biodegradable substrates that could revolutionize the capabilities of flexible PCBs in various applications.

In conclusion, flexible PCBs have undeniably transformed the way electronic devices are designed and manufactured, paving the way for smaller, more efficient, and innovative products across diverse industries. With their flexibility, durability, and reliability, flexible PCBs from PCB-togo Electronic, Inc. have ushered in a new era of electronic engineering possibilities. As technology continues to evolve, the role of flexible PCBs in shaping the future of modern electronics remains paramount. Stay connected with PCB-togo Electronic, Inc. to stay at the forefront of this exciting technological revolution.